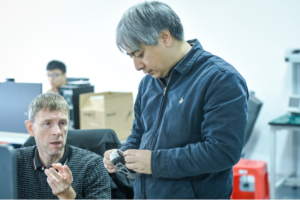

Xin Xu interviews CEO Chunsheng Liu, who shares the vision of the emerging derailleur manufacturer at the time of global supply chain crisis

Since the pandemic broke out in early 2020, the global bicycle supply chain has struggled with shortages of parts and extended lead times. L-TWOO, an emerging derailleur brand based in Zhuhai, China, grasped the opportunity and achieved multifold growth by offering original products and timely delivery. The company’s CEO Chunsheng Liu has now told the story behind the rapid rise of the manufacturer.

Tough start-up

L-TWOO was founded in 2013 by Chunsheng Liu. The brand name literally means ‘blueprint’ in Mandarin. Mr. Liu had worked as a senior mechanical engineer for 20 years before the start-up, 10 of which were spent with SRAM.

“At that time, no one could design and make derailleurs in the country, I mean independently and originally. There were indeed many counterfeits, which almost ruined the reputation of homemade bicycle components. So I saw bright prospects for a committed groupset manufacturer with professionalism and care,” Liu said, revealing his motivation, “But it turned out to be extremely difficult both technically and administratively.

“We had to balance the quality, cost, production volume with limited resources, while keeping a good level of competitiveness. That made the company’s beginning phase super tough. Fortunately, in 2016 L-TWOO came through the hard time and started to prosper. But look at my hair,” Liu joked. “Now we have more than 200 brand and OEM partners around the world. 70% of our products are delivered abroad, including Europe, South America and Southeast Asia.”

Focus on R&D

What makes L-TWOO stand out among emerging manufacturers is the great effort put into research and development. As an unwritten rule, the company spends 20% of the turnover on research activities conducted by an international R&D team, which is led by chief designers Juriy Smirnov and Sergei Vlasov and consists of designers, engineers, testers and patent attorneys. A special R&D center in Perm, Russia is dedicated to pioneering mechanical and structural research.

“Yes, we have patent attorneys in house. In the world of bicycle drivetrain, the patent barrier is almost everywhere as the leading brands have accumulated nearly 2,600 files in the past years. That’s why the first ever created department of L-TWOO was the legal department,” Liu explains. “We respect the intellectual properties of competitors, and we develop our own technical roadmap. If you rank derailleur brands by the number of patents held, L-TWOO is the third, only after Shimano and SRAM.”

A12, A13 and RX

For the coming season, L-TWOO mainly promotes three models: A12, RX and A13. “Let’s talk about our new collections. A13 and A12 are our flagships for mountain bikes, designed for intense mountain-bike racing. First, both support up to 52T cog and feature lightweight carbon fibre cage. Second, nearly all MTB models can migrate to L-TWOO A12 flawlessly thanks to the compatibility with mainstream cassettes. And third, it’s a groupset! Chainring, cogset and chain can be ordered together, which greatly reduces the complexity of sourcing and purchasing.

“A13 has 13 speeds, which is the highest system in the field of MTB. A handy feature of A12/A13 for MTB is ‘shadow design’, meaning the stretch of rear derailleur is minimized in order to reduce risk of collision. Besides top-level A12/A13, A series also have from 3×7 to 3×11 speeds available.

“As for RX, it is our high-end model for road bikes, providing 2×12 speeds. First, it’s also a groupset with front, rear, dual-control lever, etc. Second, the dual-control lever comes with ergonomic design to give nice grip and precise shifting. Carbon fibre material is applied to the lever and the rear derailleur to further reduce the weight. And third, direct-mount front derailleurs are quite effective against chain drop. A series for MTB, R series for road and F series for city or folding, L-TWOO has formed three product lines, in total 21 articles for any type of bikes. There is always the right one for your model,” Liu said.

Short lead time

Since the start of the coronavirus pandemic, the shortage of parts and extended lead times have disturbed the bicycle production in Europe. To this, L-TWOO would like to share some exciting news. “We have a short lead time, even at this moment,” Liu remarks, “Compared to competitors we have shorter and closer supply chain. Our factory is just downstairs, and we have a well-optimised schedule. When asked about the estimated range of lead time, Liu said: “Depending on specific needs, our current level is from 30-45 days to finish production. Keeping such short lead times actually attracts many new clients to L-TWOO. Comfortingly, we didn’t let any customer down even influenced by coronavirus.”

Enquiries answered within 24 hours

Finally, Liu shared his opinion on the shortage of bicycle parts: “The supply chain crisis is truly happening. Everyone in the industry is concerned about lead time, and anxious about uncertainty. The best thing we can do is to assure clients with clarity and punctuality, so I made a very hard requirement to the sales and support team, that is, any question or enquiry must be responded to within 24 hours. In addition, we just announced the new multi- lingual website where product information and catalogs are displayed in detail, all for efficient and successful cooperation.

Would you like to know more about L-TWOO’s product line? Any inquiry can be sent directly to sales@ltwoo.com or via +86 (0)756 7795001. Product information can be downloaded on the official website www.ltwoo.com/en.

BikeBiz Bicycle and cycling retail news

BikeBiz Bicycle and cycling retail news